Product Description:

HangZhou TangYi Communication Optical Fiber Cable Co.,LTD has the most advanced domestic ADSS aramid yarm stranding equipment, with the United States Dupont K49 series of high modulus aramid yarn, we can customized for clients at span range from 100 m -1800 m high quality ADSS cable.

Investing millions of dollars on national laboratory, we can provide the high and low temperature test from minus 70 degrees to 120 degrees, UV aging test, salt spray corrosion test, high tension, high torsion experiment, arc corrosion test, etc., to win customers praise with the excellent quality.

Purchasing risk:

Many small factories are without aramid yarm stranding equipment, aramid yarn is directly into the machine with flat way, tension index of those ADSS cable serious unqualified.

With low modulus aramid yarn or inadequacy aramid yarn even the high strength yarn which is with just 1/15 cost of aramid yarn as the aramid yarn , the ADSS cable will break in a short time after installing.

In same cases, ADSS need arc-resistant sheathing materials, that is AT outer sheath. While some factories do not use it which cause the outer sheath corrosion,aging fast or cracked after a period of time.

·Description

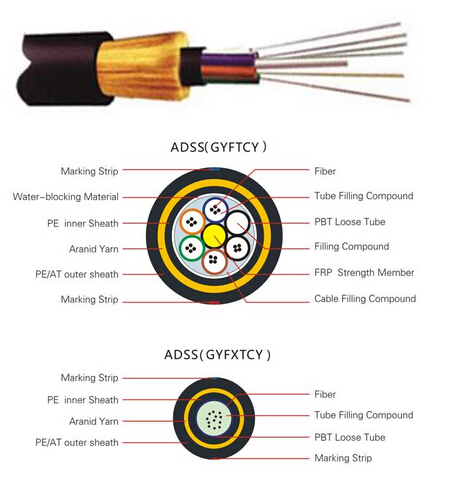

ADSS cable is loose tube stranded. Fibers, 250μm , are positioned into a loose tube made of high modulus plastics. The tubes are filled with a water-resistant filling compound. The tubes (and fillers) are stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member into a compact and circular cable core. After the cable core is filled with filling compound. it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

·Characteristics

· Can be installed without shutting off the power

· Excellent AT performance, The maximum inductive at the operating point of AT sheath can reach

25kV

· Light weight and small diameter reducing the load caused by ice and wind and the load on towers

and backprops

· Large span lengths and the largest span is over 1000m

· Good performance of tensile strength and temperature

· The design life span is 30 years

·Application

The actual status of overhead power lines is taken into full consideration when ADSS cable is being designed. For overhead power lines under 110kV, PE outer sheath is applied. FOR power lines equal to or over 110kV, AT outer sheath is applied. The dedicate design of aramid quantity and stranding process can satisfy the demand on various spans.

·Standards

ADSS cable complies with Standard IEEE P 1222 as well as IEC 60794-1.

·Optical Characteristics

| G.652 | G.655 | 50/125μm | 62.5/125μm | |

Attenuation (+20℃) | @850nm |

|

| ≤3.0 dB/km | ≤3.0 dB/km |

@1300nm |

|

| ≤1.0 dB/km | ≤1.0 dB/km | |

@1310nm | ≤0.36 dB/km | ≤0.40 dB/km |

|

| |

@1550nm | ≤0.22 dB/km | ≤0.23dB/km |

|

| |

Bandwidth (Class A) | @850nm |

|

| ≥500 MHz·km | ≥200 MHz·km |

@1300nm |

|

| ≥1000 MHz·km | ≥600 MHz·km | |

Numerical Aperture |

|

| 0.200±0.015NA | 0.275±0.015NA | |

Cable Cut-off Wavelength λcc | ≤1260nm | ≤1480nm |

|

| |

·Technical Parameters

Ref.outer diameter mm | Ref.weight kg/km | Ref.daily max.working tension kN | Max allowable working tension kN | Break strength kN | Strength member CSA mm2 | Modulus of elasticity kN/ mm2 | Heat expansion coefficient×10-6 /k | |

PE sheath | AT sheath | |||||||

12.5 | 125 | 136 | 1.5 | 4 | 10 | 4.6 | 7.6 | 1.8 |

13.0 | 132 | 142 | 2.25 | 6 | 15 | 7.6 | 8.3 | 1.5 |

13.3 | 137 | 148 | 3.0 | 8 | 20 | 10.35 | 9.45 | 1.3 |

13.6 | 145 | 156 | 3.6 | 10 | 24 | 13.8 | 10.8 | 1.2 |

13.8 | 147 | 159 | 4.5 | 12 | 30 | 14.3 | 11.8 | 1.0 |

14.5 | 164 | 177 | 5.4 | 15 | 36 | 18.4 | 13.6 | 0.9 |

14.9 | 171 | 185 | 6.75 | 18 | 45 | 22.0 | 16.4 | 0.6 |

15.1 | 179 | 193 | 7.95 | 22 | 53 | 26.4 | 18.0 | 0.3 |

15.5 | 190 | 204 | 9.0 | 26 | 60 | 32.2 | 19.1 | 0.1 |

15.6 | 194 | 208 | 10.5 | 28 | 70 | 33.0 | 19.6 | 0.1 |

16.3 | 211 | 226 | 12.75 | 34 | 85 | 40.0 | 20.1 | 0.1 |

16.8 | 226 | 242 | 15.45 | 41 | 103 | 48.0 | 24.0 | -0.4 |

17.2 | 236 | 253 | 16.2 | 45 | 108 | 51.0 | 25.1 | -0.5 |

17.9 | 249 | 266 | 18.0 | 50 | 120 | 58.8 | 26.1 | -0.8 |

Ref.outer diameter mm | Suitable span (m)

(NESC Standard,m) | |||

A | B | C | D | |

12.5 | 160 | 100 | 140 | 100 |

13.0 | 230 | 150 | 200 | 150 |

13.3 | 300 | 200 | 290 | 200 |

13.6 | 370 | 250 | 350 | 250 |

13.8 | 420 | 280 | 400 | 280 |

14.5 | 480 | 320 | 460 | 320 |

14.9 | 570 | 380 | 550 | 380 |

15.1 | 670 | 460 | 650 | 460 |

15.5 | 750 | 530 | 750 | 510 |

15.6 | 800 | 560 | 800 | 560 |

16.3 | 880 | 650 | 880 | 650 |

16.8 | 1000 | 750 | 1000 | 760 |

17.2 | 1100 | 800 | 1100 | 830 |

17.9 | 1180 | 880 | 1180 | 900 |

Storage/Operating Temperature : -40℃ to + 70℃